|

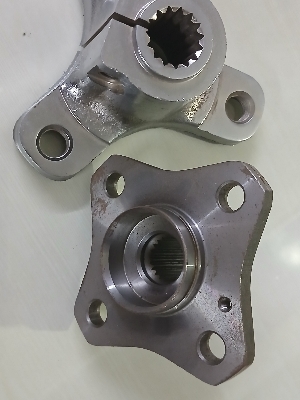

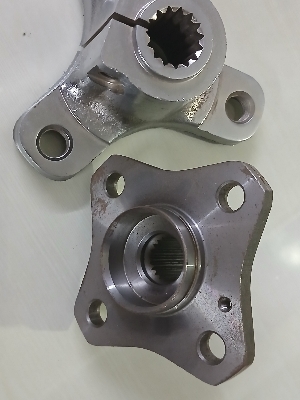

Coupling Assembly

MOQ : 1000 Pieces

Coupling Assembly Specification

- Process

- CNC Machined and Ground

- Surface Treatment

- Phosphated / Blackodised / Zinc Plated

- Product Type

- Coupling Assembly

- Material

- Alloy Steel

- Technology

- Modern Precision Engineering

- Application

- Used in Power Transmission, Mechanical Equipment, and Automotive Industries

- Dimension (L*W*H)

- Standard and Custom Sizes Available

- Weight

- Varies According to Size (Typically 0.5 5 kg)

- Color

- Black / Metallic / Silver

- Shock Absorption

- Good

- Corrosion Resistance

- Yes

- Assembly Type

- Bolt with Set Screw

- Tolerance

- ±0.01 mm

- Shape

- Cylindrical

- Maintenance

- Low

- Working Life

- > 1,000,000 cycles

Coupling Assembly Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Payment Terms

- Cash Against Delivery (CAD)

- Supply Ability

- 500000 Pieces Per Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Domestic Market

- All India

About Coupling Assembly

Coupling Assembly

We have achieved high acclamation in the industry for offering a top-of-the-line gamut of Coupling Assembly. Due to their corrosion resistant surface, our couplings are quite popular in industry. Available in varied specifications, these couplings are excellent in durability and superior in quality. Our customers can avail from us this Coupling Assembly at cost effective prices. We manufacture a wide range of couplings from quality raw materials.

Robust Performance & Durability

Designed with advanced precision engineering, this coupling assembly assures reliable performance even in challenging environments. Its corrosion-resistant alloy steel build and quality surface finishes not only protect it from harsh conditions but also contribute to its prolonged working life and consistent functionality.

Flexible Sizing & Versatile Applications

Available in both standard and custom dimensions, these assemblies cater to diverse industrial requirements. Their cylindrical form, combined with excellent shock absorption, makes them suitable for power transmission setups, automotive drive systems, and a range of mechanical equipment.

FAQs of Coupling Assembly:

Q: How does the coupling assembly achieve corrosion resistance?

A: The coupling assembly is treated with surface finishes such as phosphating, blackodising, or zinc plating, which protect it from rust and environmental wear, ensuring prolonged durability.Q: What is the recommended usage for this coupling assembly?

A: It is primarily used for power transmission in industrial machinery, automotive systems, and various mechanical equipment, providing reliable connection and shock absorption in demanding conditions.Q: When should I consider using custom sizing?

A: Custom sizing is recommended if your equipment has specific spatial or operational requirements that standard dimensions cannot meet, ensuring a perfect fit and optimal performance.Q: Where can this coupling assembly be installed?

A: This assembly can be installed in mechanical and automotive systems requiring precise power transfer, and is suitable for indoor and outdoor operations due to its corrosion-resistant and robust design.Q: What manufacturing process is used for the coupling assembly?

A: It is produced using CNC machining and ground to tight tolerances (0.01 mm), enhancing accuracy, smoothness, and compatibility with cutting-edge mechanical systems.Q: How does the bolt with set screw assembly type benefit maintenance?

A: The bolt with set screw design enables quick assembly and disassembly, minimizing maintenance efforts and reducing downtime, which is advantageous in industrial setups.Q: What is the expected working life of this coupling assembly?

A: With its durable materials and modern engineering, the assembly delivers a working life exceeding 1,000,000 cycles, ensuring long-term, dependable operation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Harvestor combined and tractor combined components Category

|

LIGHT PRECISION INC.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry