|

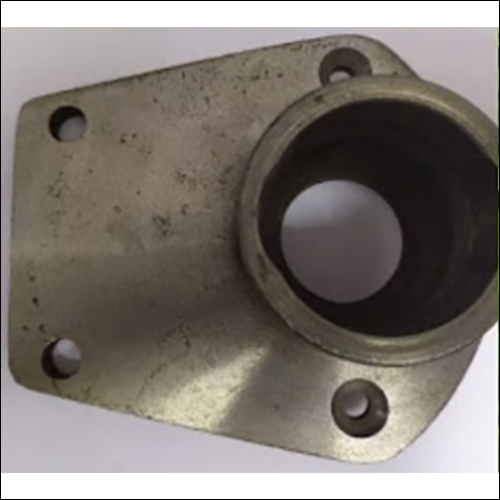

CNC Machined Components

CNC Machined Components Specification

- Thread Type

- Metric, UNC, UNF, Custom Threads

- Weight

- Varies as per size and material

- Size

- As per customer specification, micro to large size

- Method

- CNC Precision Machining

- Spindle Speed

- Up to 12000 RPM

- Load Capacity

- Up to 2000 kg (as per part design)

- Shape

- Round, Square, Custom, Complex Geometries

- Accuracy

- Up to 0.005 mm

- Coating

- Zinc, Nickel Plating, Black Oxide, Customized

- Type

- Machined Component

- Material

- Aluminum, Stainless Steel, Brass, Mild Steel, Titanium

- CNC

- Yes

- Tolerance

- 0.01 mm

- Surface

- Anodized / Polished / Powder Coated

- Use

- Mechanical Parts, Industrial Machinery

- Application

- Automotive, Aerospace, Electronics, Medical Devices

- Usage & Applications

- Precision Engineering, Assembly Parts, Automotive Fittings, Industrial Automation

CNC Machined Components Trade Information

- Minimum Order Quantity

- 100 Pieces

- Payment Terms

- Cash Against Delivery (CAD)

- Supply Ability

- 500000 Pieces Per Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Domestic Market

- All India

About CNC Machined Components

CNC Machined Components

Backed by the team of adroit professional & experience in this industry, our company has emerged as one of the renowned manufacturers and suppliers of CNC Machined Components. These components are sturdy in their construction and excellent in durability. We make sure that we use quality tested raw materials for manufacturing these components. Before supplying in market, all these CNC Machined Components are tested on various quality parameters.

Precision Meets Versatility

Each component is manufactured with attention to detail, ensuring accuracy up to 0.005 mm and adaptability across varied industry requirements. Our advanced CNC processes support round, square, complex, and custom shapes in materials like aluminum and titanium, making us a reliable choice for demanding projects or intricate assemblies.

Comprehensive Finishing and Treatment Options

Choose from a wide array of surface finishes, such as mirror polish, satin, bead blasted, anodized, and powder coated, for both functional performance and aesthetic appeal. Heat treatment processesincluding case hardening, tempering, and annealingare available on request to further enhance part durability and load capacity.

Robust Quality Assurance and Packaging Solutions

We maintain strict quality standards with meticulous inspections using CMMs, profile projectors, hardness testers, and surface roughness testers. To ensure component integrity, we offer secure packaging options ranging from export cartons and wooden cases to custom solutions, adapted for global shipments.

FAQs of CNC Machined Components:

Q: How do I request a customized CNC machined component with specific dimensions and finishes?

A: You can provide your 2D or 3D CAD drawings or consult our design support team to finalize your requirements, including material, finishing options such as mirror, satin, or bead blasted, and any custom features. Our engineers will guide you through the process to ensure your specifications are met.Q: What materials and shapes can you machine, and do you support complex geometries?

A: We offer machining in aluminum, stainless steel, brass, mild steel, and titanium. Shapes include round, square, and fully customized or complex geometries, making our service suitable for diverse applications in precision engineering.Q: When will I receive my order, and are samples available before bulk production?

A: Lead times typically range from 2 to 4 weeks, depending on order size and complexity. Samples can be provided upon request to verify quality and specifications prior to full-scale production.Q: How do you ensure the quality and accuracy of each machined part?

A: Quality control involves multi-stage inspection with CMM, profile projector, hardness tester, and surface roughness tester, adhering to ISO 9001:2015, RoHS, DIN, JIS, and ASTM standards for consistent accuracy and reliability.Q: What benefits do your heat treatment and coating services provide?

A: Heat treatments such as case hardening, tempering, and annealing enhance mechanical strength and durability, while coatings like zinc, nickel plating, and black oxide offer extended corrosion resistance and custom functionality depending on your application.Q: Where are your CNC machined components used, and who are your typical customers?

A: Our components are widely employed in automotive, aerospace, electronics, medical, and industrial automation sectors. We frequently serve OEMs, ODMs, precision engineering firms, and industrial assembly lines, both domestically and for export markets.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Turned Components Category

Feeder Gear

Price Range 150.00 - 200.00 INR / Piece

Minimum Order Quantity : 50 Pieces

Product Type : Feeder Gear

Application : Industrial

Surface : Galvanized

Color : Dark Gray

Bearing Housing 955.1

Price Range 200.00 - 300.00 INR / Piece

Minimum Order Quantity : 50 Pieces

Product Type : Bearing Housing 955.1

Application : Industrial

Surface : Galvanized

Color : Dark Gray

Male 620

Price Range 20.00 - 30.00 INR / Piece

Minimum Order Quantity : 50 Pieces

Product Type : Male 620

Application : Industrial

Surface : Painted

Color : Golden

Sleeve Output Housing

Price Range 60.00 - 70.00 INR / Piece

Minimum Order Quantity : 50 Pieces

Product Type : Sleeve Output Housing

Application : Industrial

Surface : Galvanized

Color : Dark Gray

|

LIGHT PRECISION INC.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry